Affordable Wholesale Deep Groove Ball Bearing for Sale

By:Admin

A leading manufacturer of deep groove ball bearings, {company name}, has recently launched a new line of wholesale deep groove ball bearings, providing customers with high-quality products at competitive prices. This new offering is expected to meet the growing demand for reliable and efficient bearings in various industries such as automotive, machinery, and industrial applications.

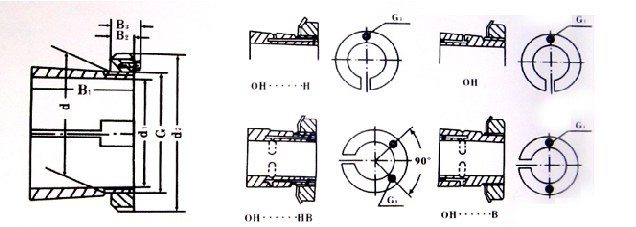

Deep groove ball bearings are versatile, self-retaining bearings with solid outer rings, inner rings, and ball and cage assemblies. They are simple in design, non-separable, suitable for high speeds and are robust in operation, requiring little maintenance. These bearings are widely used in various applications, including electric motors, pumps, automotive, and industrial machinery.

{company name} has positioned itself as a prominent player in the global bearing market, with a strong focus on quality, innovation, and customer satisfaction. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that its products meet the highest industry standards. In addition to standard deep groove ball bearings, {company name} offers custom solutions to meet specific customer requirements.

The new line of wholesale deep groove ball bearings from {company name} is available in a wide range of sizes and configurations to cater to diverse customer needs. Customers can choose from open and sealed variants, as well as bearings with different cage materials, including steel, brass, or polyamide. This flexibility enables customers to find the ideal bearing for their specific application, whether it be for high-speed operations or high-temperature environments.

Furthermore, {company name} offers technical support and engineering expertise to help customers select the right bearing for their application. This includes assistance with bearing selection, lubrication, installation, and maintenance, ensuring that customers can maximize the performance and longevity of their equipment.

The launch of the wholesale deep groove ball bearing line underscores {company name}'s commitment to providing cost-effective solutions without compromising on quality. By offering competitive pricing for bulk orders, the company aims to support customers in optimizing their supply chain and reducing overall costs.

With a global distribution network and a focus on customer service, {company name} is well-positioned to serve customers around the world. The company has established strong relationships with distributors, OEMs, and end-users, allowing for efficient and reliable delivery of its products to various industries and markets.

In addition to the wholesale deep groove ball bearings, {company name} offers a comprehensive range of other bearing types, including angular contact ball bearings, spherical roller bearings, cylindrical roller bearings, and tapered roller bearings. This diverse product portfolio, combined with the company's expertise and commitment to quality, has earned {company name} a reputation as a trusted supplier in the bearing industry.

As the demand for reliable bearings continues to grow, {company name} remains dedicated to meeting the evolving needs of its customers. Through innovative products, outstanding service, and a strong focus on quality, the company is poised to maintain its position as a leader in the global bearing market.

Company News & Blog

Get Affordable Adapter Sleeves from China's Leading Wholesalers - Enjoy Global Shipping Options

, China Adapter Sleeve, Sz-wholesale.com, and worldwide delivery.Are you in need of adapter sleeves for your manufacturing or construction projects? Look no further than SZ-wholesale.com, the premier online wholesaler for adapter sleeves in China.At SZ-wholesale.com, we offer a wide range of adapter sleeves to fit your specific needs. Whether you need sleeves for bearing applications, conveyor belt systems, or any other machinery, our products are designed to provide reliable performance at an affordable price.Our adapter sleeves are made from high-quality materials, such as stainless steel or carbon steel, and are precision crafted to ensure a perfect fit. They are easy to install and remove, and designed to withstand the rigors of heavy-duty use.We understand that time is money in the business world, and that's why we offer worldwide delivery. No matter where you are located, our adapter sleeves can be delivered to you quickly and efficiently. Whether you are in Australia, Europe, or anywhere in between, we've got you covered.And best of all, as a wholesale supplier, we offer unbeatable prices on all of our products. By purchasing in bulk, you can save money and keep your operations running smoothly.So why wait? Visit sz-wholesale.com today and discover the advantages of shopping with the leading adapter sleeve wholesaler in China. Whether you need one sleeve or a hundred, we are here to help you get the job done right.

Types of Non-standard OEM Bearing Good Quality Long Life 45.242*73.431*19.812 mm LM102949/10 Tapered Roller Bearing: - Non-standard size - OEM brand - Good quality - Long life - 45.242*73.431*19.812 mm dimensions - LM102949/10 model of tapered roller bearing

Types and CharacteristicsNon-standard OEM brand bearings are bearings that do not conform to standard specifications. These bearings are typically designed to meet specific application requirements or industry standards. The LM102949/10 tapered roller bearing is one such non-standard bearing that boasts of excellent quality and long life. Let's take a look at the different types of non-standard OEM brand bearings and their characteristics.1. Ball bearings - These bearings comprise of a spherical rolling element and are used to bear radial and axial loads. They are characterized by their low friction and high-speed performance.2. Roller bearings - Roller bearings are bearings that use cylindrical, tapered or spherical rolling elements. They are used primarily in heavy-duty applications where radial and axial loads need to be supported.3. Thrust bearings - These bearings are designed to support axial loads and are typically used in applications where there is a significant amount of axial load. Thrust bearings are available in different types - including ball thrust bearings, cylindrical thrust bearings, and tapered thrust bearings.4. Needle bearings - Needle bearings are a type of roller bearing that uses a small-diameter rolling element to support radial loads. They are typically used in applications where space is limited or where high accuracy is required.5. Plain bearings - Plain bearings consist of a plain metal sleeve that supports a rotating shaft. They are used primarily in low-speed applications where lubrication can be easily maintained.In conclusion, non-standard OEM brand bearings are designed to meet specific application requirements or industry standards. The LM102949/10 tapered roller bearing is one such non-standard bearing that boasts of excellent quality and long life. It is important to choose the right type of non-standard bearing for your application to ensure reliable and efficient performance.

Revolutionary Advances in Automotive Technology: The Latest Updates Unveiled!

Innovative Manufacturing Company Leads the Way in Product DevelopmentIn the highly competitive manufacturing industry, companies must continuously innovate and deliver valuable products to stay ahead. This has been the driving force behind the innovative manufacturing company – leading the way in product development. They strive to deliver ground-breaking technology solutions, improve efficiency, and enhance customer satisfaction by providing exceptional products and services.The company has a reputation for reliable and efficient production, using advanced technology and modern manufacturing processes. It boasts a vast range of products that cater to different industries and businesses, including automotive, electronics, textiles, and telecommunications. With its strong research and development team, the company has expanded from traditional manufacturing into new, innovative areas such as semiconductor production, robotics, and automation. At the forefront of their product development is their flagship artificial intelligence (AI) platform that helps businesses to optimize processes and improve productivity. This has garnered significant interest from industry players looking to automate their manufacturing processes and save time and money. By leveraging AI capabilities, the company is able to offer practical solutions that deliver exceptional results.The company understands the importance of sustainability and responsible production, and thus has made this a core part of its operations. Their focus on environmentally friendly production processes, including the use of solar panels to power their manufacturing plants, makes them a sustainability leader in the industry. The company is also committed to corporate social responsibility, supporting local communities, and encouraging employee volunteerism.The integration of advanced technologies into its manufacturing has allowed the company to produce high-quality products in less time, while reducing waste and optimizing production. The innovative manufacturing company has been a leading force in the industry for years, with a unique blend of cutting-edge technology and manufacturing expertise. Several areas have contributed to the company's ongoing success, including its focus on research and development, its commitment to technology and innovation, and its customer-centric approach. Its advanced supply chain management systems have helped the company to adapt to changing market conditions and manage overall production costs. The company has an ongoing commitment to keep up with market trends, which is why it has been able to produce some of the best AI-driven technology products in the industry. They are known for their continuous refinement of their manufacturing processes to deliver increasingly higher quality products, tailored to specific customer needs. With a strong R&D team that keeps up-to-date with technological advancements, the company has been able to capitalize on new trends to stay competitive in an ever-changing market.In a world that depends on technology, the innovative manufacturing company is playing a role in shaping our future and redefining the manufacturing industry for years to come. With a team of experts that bring together a unique set of skills and diverse backgrounds, the company has been able to foster a culture of creativity, innovation, and collaboration. Their collective goal is to continue providing the best products and services to customers, while constantly challenging themselves to improveIn conclusion, the innovative manufacturing company has been a long-standing pillar in the industry, known for delivering reliable and innovative products that meet the needs of customers. With a focus on customer satisfaction, sustainability, and technological innovation, they have continued to attract new clients while retaining their existing customer base. Their unique blend of advanced technology and manufacturing expertise puts the company at the forefront of the industry, and they will continue to drive the manufacturing sector forward with the latest technology innovations.

and Hub Units, China Daybec, Wheel Bearing Manufacturer, Wheel Hub Unit Manufacturer, High-Quality Wheel Bearings, International Market.As we have mentioned earlier, China Daybec is one of the leading Wheel Bearing and Wheel Hub Unit Manufacturer in China. They specialize in producing high-quality wheel bearings and wheel hub units that are widely used in the global market. The company has been in the industry for years, and their commitment to creating high-quality products has been proven by their excellent track record.China Daybec's expertise is in the production of OEM Wheel Bearings and Hub Units, which are particularly in high demand in the international market. Their products are manufactured using state-of-the-art technology, advanced machinery, and top-quality materials, ensuring that every product that comes out meets the stringent industry standards.One of the most notable things about China Daybec is their unwavering dedication to providing high-quality products to their clients. Every product goes through a rigorous quality control process to ensure that it meets the highest standards and can withstand the toughest tests. This way, the company ensures that their customers get the best value for their money by providing them with durable and reliable wheel bearings and hub units.The company has a team of highly skilled professionals who are passionate about their work and dedicated to their roles. They are committed to providing the best customer service possible, something that has helped them establish long-lasting client relationships.Furthermore, China Daybec is keen on maintaining their strong reputation in the industry. They ensure that each product they produce meets the highest possible standards, and they continuously work towards improving their products by investing in research and development. This drive for excellence has helped them remain a top player in the industry and has attracted clients from all over the world.In conclusion, when it comes to Wheel Bearings and Hub Units, China Daybec is the market leader. They are committed to producing high-quality products that meet the highest standards for durability and reliability. The company's focus on customer satisfaction and the use of the latest technology, advanced machinery, and top-quality materials ensures that every product they produce meets or exceeds industry standards. As such, they have established themselves as one of the best Wheel Bearing and Hub Unit Manufacturers in the world. If you're looking for high-quality OEM Wheel Bearings and Hub Units, China Daybec is the perfect option.

Cylindrical Roller Bearings: A Guide to Understanding and Choosing the Right Type

IntroductionCylindrical Roller Bearings are one of the most popular types of bearings and are widely used in various industries such as automotive, aerospace, construction, and machine tools. They are designed to carry heavy radial loads and reduce friction between two rotating parts. Timken is a leading manufacturer of Cylindrical Roller Bearings and offers a wide range of product lines with various sizes and specifications.In this blog, we will discuss the benefits of using Cylindrical Roller Bearings, the different types of Timken Cylindrical Roller Bearings, and how to select the right bearing for your application.Benefits of using Cylindrical Roller Bearings1. High load carrying capacity - Cylindrical Roller Bearings are designed to carry high radial loads and can withstand heavy axial loads, making them ideal for applications with heavy loads.2. Low friction - Cylindrical Roller Bearings have a low coefficient of friction, which reduces energy consumption and improves efficiency.3. Easy installation and maintenance - Cylindrical Roller Bearings are easy to install and require minimal maintenance, reducing downtime and increasing productivity.4. Longer service life - Timken Cylindrical Roller Bearings are made with high-quality materials and advanced technologies, resulting in a longer service life and reduced maintenance costs.Types of Timken Cylindrical Roller BearingsTimken offers a wide range of Cylindrical Roller Bearings, including:1. Single-Row - Single-row Cylindrical Roller Bearings are designed to resist radial loads, and they have a single row of rollers. They are widely used in electric motors, pumps, and other machinery.2. Double-Row - Double-row Cylindrical Roller Bearings are designed to resist radial and axial loads, and they have two rows of rollers. They are ideal for applications with heavy loads and high speeds.3. Multi-Row - Multi-row Cylindrical Roller Bearings have multiple rows of rollers and are designed to carry very heavy loads. They are used in industries such as mining, cement, and steel.4. Full Complement - Full Complement Cylindrical Roller Bearings have no cage and have a maximum number of rollers. They are designed to carry heavy radial loads and are used in applications such as rolling mills and gearboxes.How to select the right Timken Cylindrical Roller BearingWhen selecting a Cylindrical Roller Bearing, there are several factors to consider, including:1. Load - Determine the load capacity required for your application and select a bearing that can handle the load.2. Speed - Determine the speed requirements of your application and select a bearing with a suitable maximum operating speed.3. Size - Determine the size of the bearing required for your application, based on the shaft diameter and housing bore.4. Lubrication - Select a bearing that is compatible with the lubrication system used in your application.ConclusionCylindrical Roller Bearings are an essential component of many machines and equipment. Timken Cylindrical Roller Bearings are designed with high-quality materials and advanced technologies, resulting in a longer service life and reduced maintenance costs. When selecting a bearing, it is important to consider factors such as load, speed, size, and lubrication to ensure the optimal performance of your equipment. With the right selection of Timken Cylindrical Roller Bearings, you can reduce downtime, increase productivity, and improve your bottom line.

Protect Your Pipes from Leaks with Rubber Gaskets - Tips from Experts

and PIPE LEAK PREVENTION.Preventing pipe leaks is essential for any plumbing system. Whether you are installing a new pipe or fixing an old one, water leaks can cause significant damage to your house. The good news is that with high-quality rubber gaskets, you can prevent water leaks and save yourself from costly repairs.When it comes to pipe systems, rubber gaskets are essential parts that seal the joints of pipes. They prevent water from leaking out and ensure that the system works efficiently. Rubber gaskets are commonly made of EPDM (Ethylene Propylene Diene Monomer) material, which is known for its durability and resilience. EPDM rubber gaskets are also resistant to extreme temperatures, UV rays, and chemicals. So, they can withstand harsh environmental conditions without getting damaged.Now let's discuss how you can prevent pipe leaks with rubber gaskets.1. Choose the Right GasketWhen selecting a rubber gasket, it's essential to choose the right size and material that matches the pipe's diameter and the application's specific requirements. For instance, if you need a gasket for drinking water or food-grade applications, you should choose a gasket made from EPDM material rather than other types of materials that are not safe for human consumption.2. Proper InstallationProper installation of the rubber gasket is necessary to ensure that it works correctly. Make sure to clean and dry the pipe before inserting the gasket. The gasket should be inserted in such a way that the flange provides enough compression to create a watertight seal. If done correctly, the rubber gasket will expand to seal the gap between the two pipes and prevent any water leakage.3. Regular MaintenanceIt's crucial to check your plumbing system for any leaks regularly. Signs of water leakage can be seen around the pipe joints. If you notice any leaks, it's essential to replace the rubber gasket immediately to prevent any further damage to the pipe system.4. Replace Old GasketsOver time, rubber gaskets can wear out and become less effective in preventing water leaks. Therefore, it's necessary to replace the old gaskets periodically to ensure that your pipe system remains leak-free. The frequency of replacement can vary depending on the usage and environmental factors.In conclusion, preventing water leaks in plumbing systems is essential to avoid costly repairs. Using high-quality rubber gaskets made from EPDM material can effectively prevent pipe leaks. Proper installation, regular maintenance, and timely replacement of the old gaskets can ensure reliable performance of the system. So, if you're looking for a durable and effective solution to prevent water leaks, consider using EPDM rubber gaskets for your plumbing system.

Top Bearings Supplier in China: Delivering Exceptional Quality to Global Clients

Title: China's Auto Bearing Industry Poised for Significant Growth Despite Global ChallengesIntroduction:Amidst global challenges faced by the automotive industry, China's auto bearing sector, with its undeniable potential and unwavering innovation-driven approach, stands poised for significant growth. China Auto Bearing, a leading company in this sector, has emerged as a frontrunner in navigating these turbulent times. Leveraging state-of-the-art manufacturing techniques and an unwavering commitment to quality, China Auto Bearing continues to set new benchmarks for the industry.Background:China Auto Bearing has become a prominent player in the global market, owing to its unwavering focus on research and development, streamlined production processes, and a robust quality control framework. The company has consistently strived for technological advancements to cater to the growing demands of the automotive industry, domestically and internationally.Furthermore, China Auto Bearing has built a strong reputation for its dedication to customer satisfaction and commitment to maintaining professional relationships. With a diverse product portfolio, including a wide range of bearings that cater to automobiles, trucks, and other vehicles, the company has fostered long-standing partnerships with major automakers, contributing significantly to their success.Market Analysis:Despite the challenges faced by the automotive sector globally, China's auto bearing industry has maintained stable growth. A combination of factors, such as increasing demand for automobiles, continuous technological advancements, and government initiatives promoting the electric vehicle industry, has created a favorable environment for market expansion.The rise in disposable income, coupled with the growth of the middle-class population in China, has led to an increase in vehicle purchases, bolstering the demand for auto bearings. Additionally, the government's push to reduce carbon emissions has paved the way for the rapid adoption of electric vehicles, boosting the demand for specialized bearings in this segment.Product Innovation:Recognizing the need to stay ahead in a highly competitive market, China Auto Bearing has consistently invested in research and development activities. The company's cutting-edge technologies and innovative designs have resulted in the production of high-quality bearings that meet the stringent requirements of modern vehicles.Moreover, China Auto Bearing is driving advancements in the electric vehicle sector by developing specialized bearings capable of withstanding the unique demands of these vehicles. With features like reduced friction, higher load capacity, and improved durability, these bearings contribute to the overall performance and efficiency of electric vehicles.Quality Control and Certification:China Auto Bearing places utmost importance on maintaining the highest standards of quality. The company adheres to strict quality control measures at every step of the manufacturing process, ensuring that all its products meet both national and international standards. Furthermore, China Auto Bearing has obtained various certifications, including ISO 9001:2015 and IATF 16949:2016, strengthening its commitment to excellence.Sustainable Practices:China Auto Bearing acknowledges its responsibility towards environmental conservation and sustainable business practices. The company is actively exploring ways to reduce its carbon footprint by optimizing production processes, minimizing waste, and adopting energy-efficient technologies. With an emphasis on eco-friendly materials and sustainable manufacturing, China Auto Bearing aims to lead the way towards a greener automotive industry.Conclusion:China Auto Bearing has established itself as a leading player in the auto bearing industry, driven by its unwavering commitment to innovation, high-quality products, and customer satisfaction. With the market's significant growth potential, especially in the electric vehicle sector, the company is well-positioned to capitalize on emerging opportunities. By continuously investing in research and development and upholding stringent quality control measures, China Auto Bearing is poised to shape the future of the global auto bearing industry.

Discover the Latest Breakthrough: Nylon Indexing Discs Revolutionize Industry Standards

Title: Nylon Indexing Disc: Revolutionizing Industrial Applications with Enhanced Efficiency Introduction:In an era where digitalization and automation drive rapid industrial advancements, innovation has become the cornerstone of success for companies across various sectors. One such groundbreaking invention, the Nylon Indexing Disc, has caught the attention of manufacturers, promising to transform traditional industrial processes with its exceptional efficiency and durability.Background:The Nylon Indexing Disc, developed by a leading global manufacturing company, represents a breakthrough in industrial technology. The disc is specifically engineered to replace conventional indexing solutions, revolutionizing many aspects of modern production processes. With its unique design and superior performance, this revolutionary product is poised to reshape industries' operational efficiency and reliability.Key Features:1. Durable Material:The Nylon Indexing Disc is crafted from high-strength nylon, a material renowned for its remarkable durability and resistance to wear and tear. This choice of material ensures that the disc can withstand repetitive and heavy-duty applications without compromising its performance.2. Excellent Indexing Accuracy:Equipped with precise indexing notches and robust teeth, the disc offers unparalleled accuracy during rotational movements. The finely tuned indexing system allows manufacturers to achieve high-precision positioning and seamless synchronization within their machinery, leading to enhanced productivity and reduced downtime.3. Improved Load-Bearing Capacity:The Nylon Indexing Disc's design allows for a significantly increased load-bearing capacity compared to traditional indexing methods. This feature enables manufacturers to handle heavier workpieces without jeopardizing the operational efficiency of their machinery. Consequently, production processes can be optimized, resulting in enhanced output and minimized lead times.4. Enhanced Versatility:Apart from its core functionalities, the Nylon Indexing Disc boasts remarkable versatility, making it suitable for a wide range of industrial applications. From assembly lines to packaging and from machining to robotics, this cutting-edge innovation can seamlessly integrate into various manufacturing processes, unlocking new possibilities for industrial automation.Impact on Industrial Processes:1. Increased Efficiency:By leveraging the Nylon Indexing Disc's advanced features, manufacturers can streamline their production lines, resulting in increased overall efficiency. This new indexing solution accelerates operations, eliminates unnecessary downtime, and maximizes the utilization of machinery, allowing companies to meet growing demands promptly.2. Heightened Precision:Precision plays a pivotal role in contemporary manufacturing processes, particularly in industries such as automotive, electronics, and aerospace. The Nylon Indexing Disc's superb indexing accuracy ensures precise positioning and synchronization, thereby improving the quality of assembled components and finished products.3. Cost Savings:With its ability to handle higher loads, the Nylon Indexing Disc enables manufacturers to optimize their production capacities, ultimately leading to cost savings. By reducing the need for additional equipment or infrastructure, this innovative solution helps companies enhance their bottom line while staying competitive in the market.4. Reliable Performance:Thanks to the use of robust nylon material, the indexing disc offers exceptional resilience, longevity, and resistance to wear. This durability reduces maintenance costs, prolongs the lifespan of the machinery, and contributes to a stable and reliable production environment for businesses.Conclusion:The Nylon Indexing Disc is a pioneering creation that has the potential to transform industrial processes in numerous sectors worldwide. With its durable material, enhanced indexing accuracy, increased load-bearing capacity, and versatility, this innovative solution promises improved efficiency, precision, cost savings, and overall reliability for manufacturers. As industries continue to evolve, embracing this revolutionary technology will undoubtedly contribute to a successful and resilient future in manufacturing.

Deep Groove Ball Bearings for Flange Applications in China

China Flange Deep Groove Ball Bearing Holds Inauguration Ceremony for New Production LineDongguan, China – China Flange Deep Groove Ball Bearing, a leading manufacturer of high-quality bearings, recently held an inauguration ceremony for a new production line at its Dongguan facility. The ceremony was attended by company executives, including CEO Mr. Zhang, representatives from local government, and other distinguished guests.The new production line will significantly increase the company's production capacity, allowing it to meet the growing demand for its products. With automated machinery and advanced production techniques, the line is expected to produce superior bearing products that meet international standards.In his opening remarks, Mr. Zhang expressed his gratitude to all attendees and highlighted the company's commitment to quality and innovation. He emphasized that the new production line is a testament to China Flange's dedication to meeting customer needs and staying ahead of the competition.The company was founded in 2005 and has since become a leading manufacturer of flange deep groove ball bearings. Its quality products are known for their durability, precision, and reliability, making them suitable for a wide range of industrial applications.China Flange's bearings are widely used in precision instruments, aerospace, machinery, and other industries. With more than 100 employees and advanced production technology, the company has established a strong reputation in the global market.The company uses only high-grade steel and advanced production techniques to produce its bearings. Its strict quality control ensures that each bearing meets international standards, exceeding customer expectations.In addition to producing high-quality bearings, China Flange is committed to customer satisfaction. The company offers 24/7 support to help customers troubleshoot any issues, and it is constantly looking for ways to improve its products and services.The company's dedication to customer satisfaction has helped it to become a leading manufacturer of bearings in China, with a growing global presence. China Flange has established partnerships with customers in Asia, Europe, and North America, and its products are used by leading companies in a wide range of industries.With the new production line, China Flange is well-positioned to continue meeting customer needs and staying ahead of the competition in the global market. The company is committed to maintaining its high standards of quality and innovation, and it looks forward to a bright future as a leading manufacturer of bearings.Overall, the inauguration of China Flange's new production line is a significant milestone for the company and an important development for the global bearings market. The line's advanced technology, combined with the company's commitment to quality and customer satisfaction, is sure to make China Flange a force to be reckoned with in the industry for years to come.